자동화 설비안내

주식회사 제일의 자동화 설비안내 입니다.

Automation Faciities

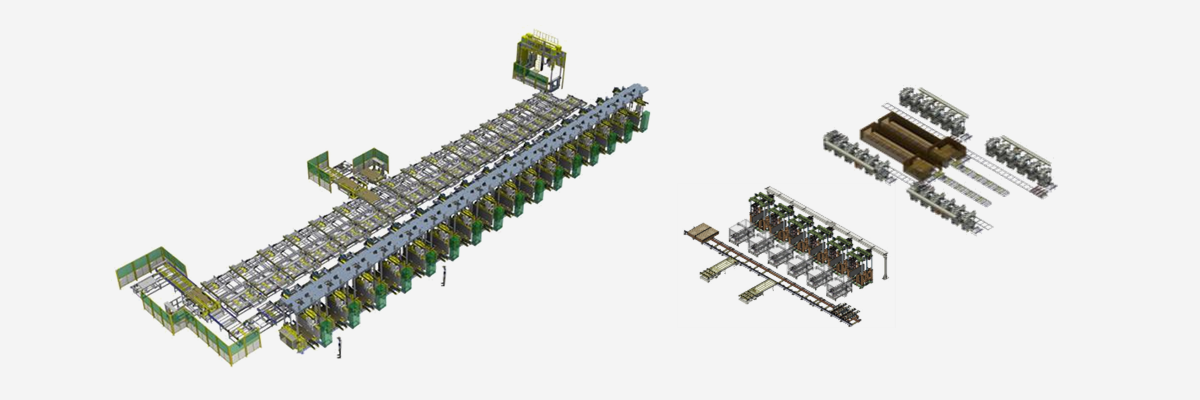

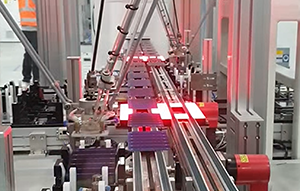

냉장고

- 캐비 발포

- 도어 발포

- 내상인서트

- 콤프 체결기

- 보호 비닐 커팅

- 내상 피어싱

- 도어 발포 라인

- 금형 대차

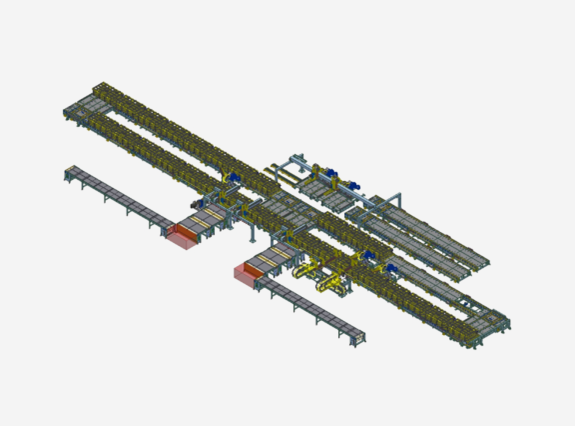

- 캐비넷 발포 라인

- 캐비넷 발포 라인

- refrigerator wet part

세탁기

- 수축포장기

- 6축 체결기

- 반전기

- 17축 체결기

- 판금 라인

- 판금 라인

- 베어링 프레스

- EPS 포장

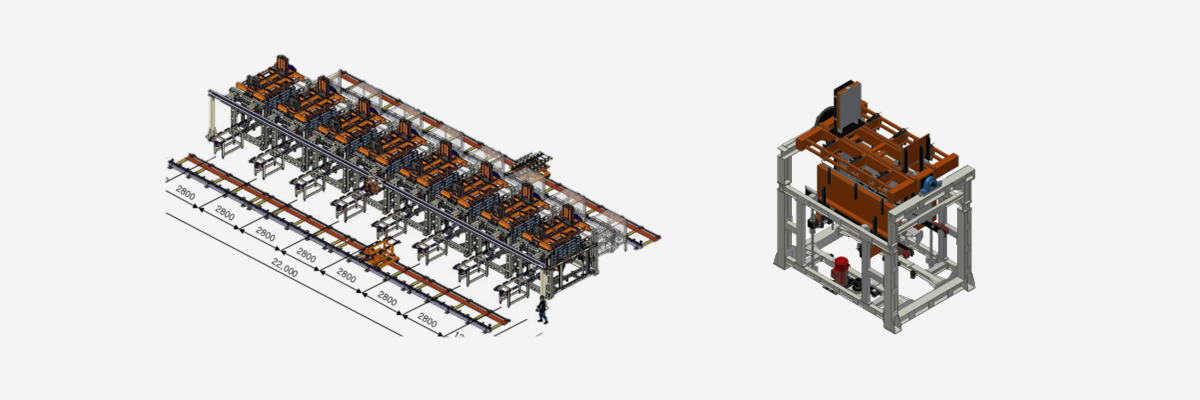

냉장고 - Precision Fixture

- Type Application method

- Production method Face-Up

- Production Model SBS, 2door

- Service Time 45sec

- Cycle Time 15sec

- Up/Down Hyd 'System (individual or composite)

- Side Wall Left / right individual operation possible Automatic (Servo Motor)

- Change of model Separate device configuration / Full automatic

- Injection method Individual Mix head or 1MixHead / 6 Fixture

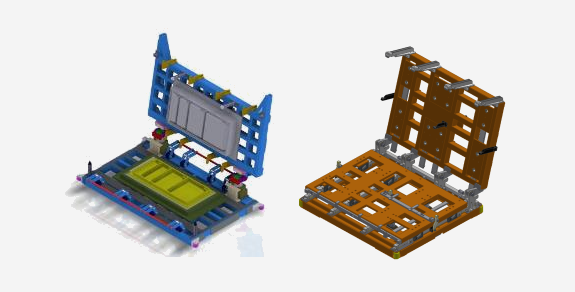

냉장고 - Rotary Fixture

- Type Application method

- Production method Face-Up

- Production Model SBS, 2door

- Service Time 45sec

- Cycle Time 15sec

- Up/Down Hyd 'System (individual or composite)

- Side Wall Left / right individual operation possible Automatic (Servo Motor)

- Change of model Separate device configuration / Full automatic

- Injection method Individual Mix head or 1MixHead / 6 Fixture

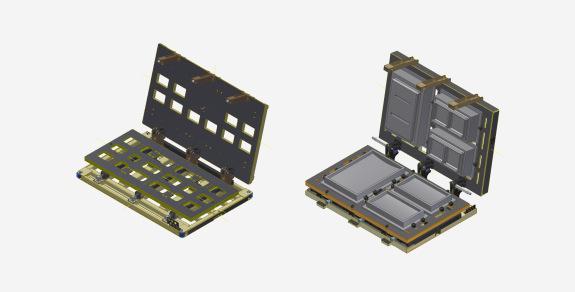

냉장고 - Hybrid Fixture

- Type Application method

- Production method Face-Up

- Production Model SBS, 2door

- Service Time 45sec

- Cycle Time 15sec

- Up/Down Hyd 'System (individual or composite)

- Side Wall Left / right individual operation possible Automatic (Servo Motor)

- Change of model Separate device configuration / Full automatic

- Injection method Individual Mix head or 1MixHead / 6 Fixture

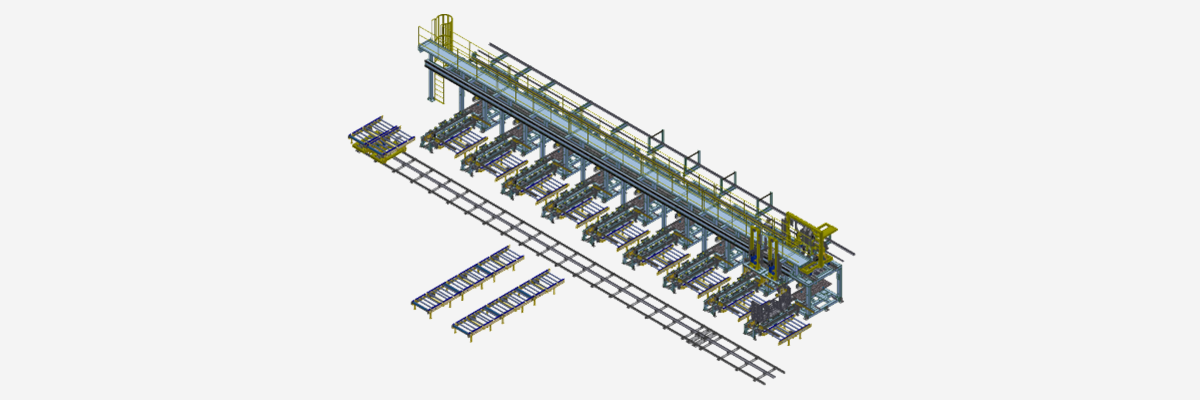

냉장고 - Door P/U Foaming

- Carousel Type

Carousel Type Cabinet Face Down method of LinFlex Type Lay-out method of Face-up type applying Foam Line line and can be divided into preheating main working section and preheating section.

The basic work process consists of Open, Unloading, Buffer (Manual Clean), Loading, N2 Injection, Injection and Close.

Jig Fixture is a type that separates the upper part of the jig fixture. The upper part of the fixture is separated from the open section and transferred to the process. In the close section, the upper panel is transferred to the injection section. It is possible to use Jig Change in a separate Q.D.C section.

The equipment configuration consists of Main Feeding M / C that feeds the entire jig at one time, a section that feeds the fixture top plate, and a Diverter section that feeds the jig to the back row, a conveyor section, and a Q.D.C section.

The Q.D.C interval can be be 1: 1 replaced by applying the pre-standby buffer interval. An important option is a facility that can be configured for Face Down and Face Up Type equipment.

- Hi Class Carousel Type

The Carousel Type Door Foam Line is a lay-out of quadrilateral and is a facility exclusive for 4-door French Door from Side By Side.

Cycle Time can be configured according to the option, but it can be configured 15sec. Generally, two, three, and four doors are produced in one mold carrier. The basic work process consists of Open, Unloading, Door Liner (plastic door) insertion, Out door insertion, Injection, Close.

The equipment configuration consists of main feeding M / C that feeds the entire jig at one time in addition to the basic work process equipment, a Diverter section that feeds the jig to the downstream, a conveyor section and a Q.D.C section.

Normally, the door liner (plastic door) and the out door section are equipped with manual and automatic options, In addition, it is a facility that can automatically replace 1: 1 mold carrier and inner jig when changing door jig.

Injection usually consists of 2-head and 4-head. In case of 4-door French door, more than 4_head multi head is applied.

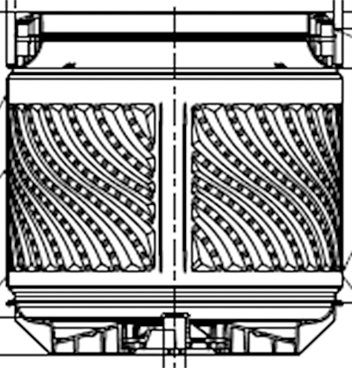

Mold Carrier

Mold Carrier is able to mount various types of jigs such as Compact, 4-Door French Door and Medical Refrigerator Door, and we also produce special type mold carrier to meet customer's request.

The basic mold carrier types are fixed mold carrier and height variable mold carrier, and optional Jig Auto Change function can be included.

Mold Carrier Size is custom made.

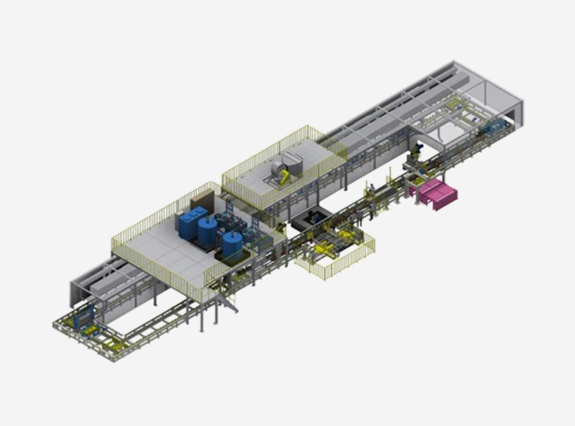

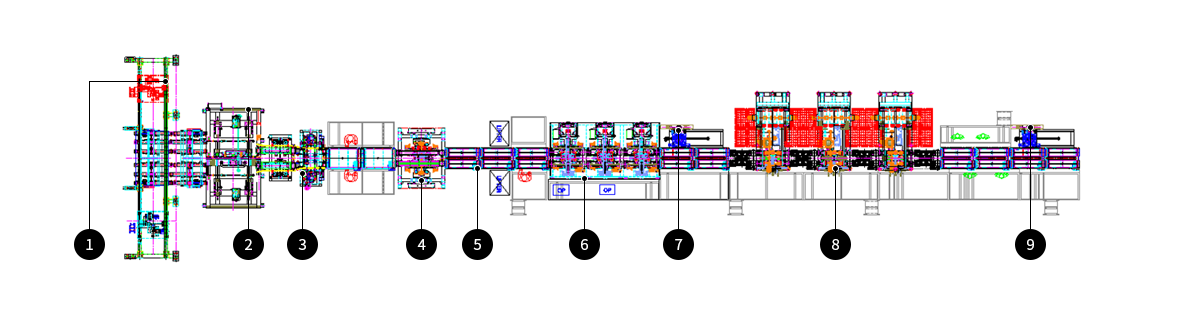

세탁기- Cabinet

1. SHEET FEEDER

1. SHEET FEEDER 2. 4-P BENDER

2. 4-P BENDER 3. TURNER

3. TURNER 4. LOWER CAULKING

4. LOWER CAULKING 5. SPRING CAULKING

5. SPRING CAULKING 6. BOTTOM CAULKING

6. BOTTOM CAULKING

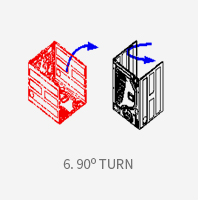

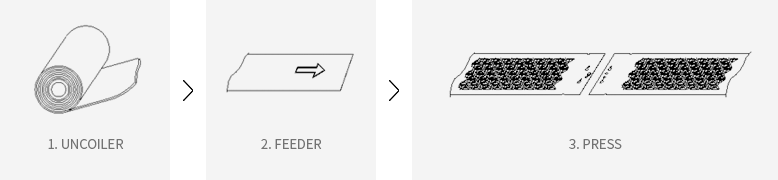

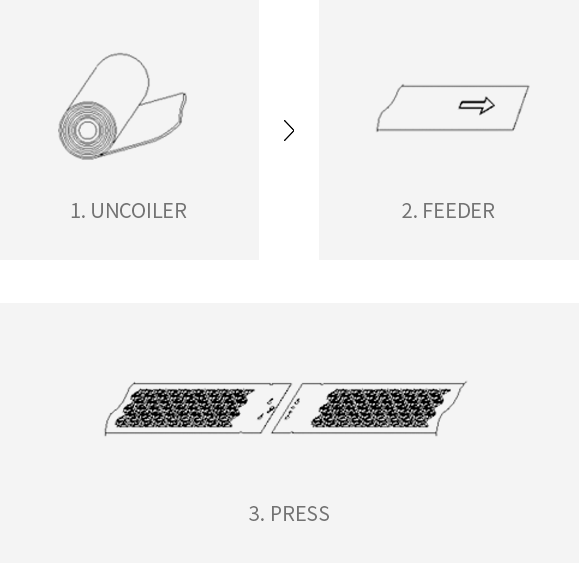

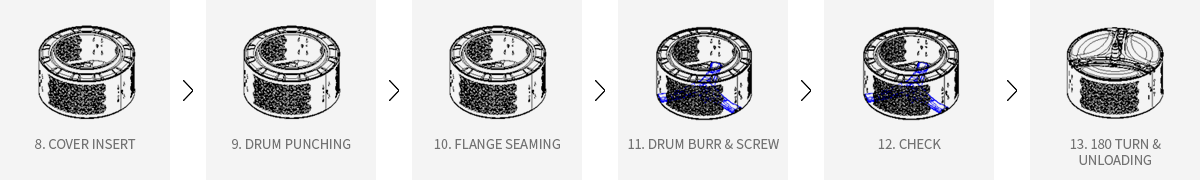

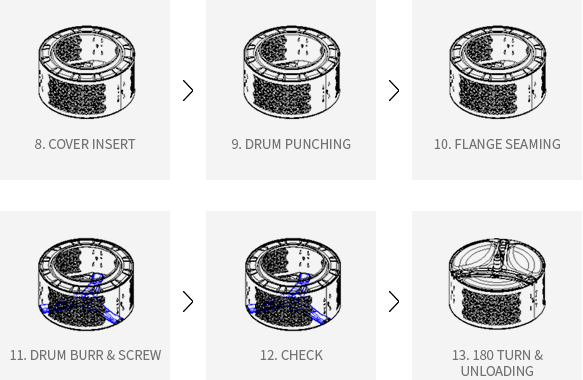

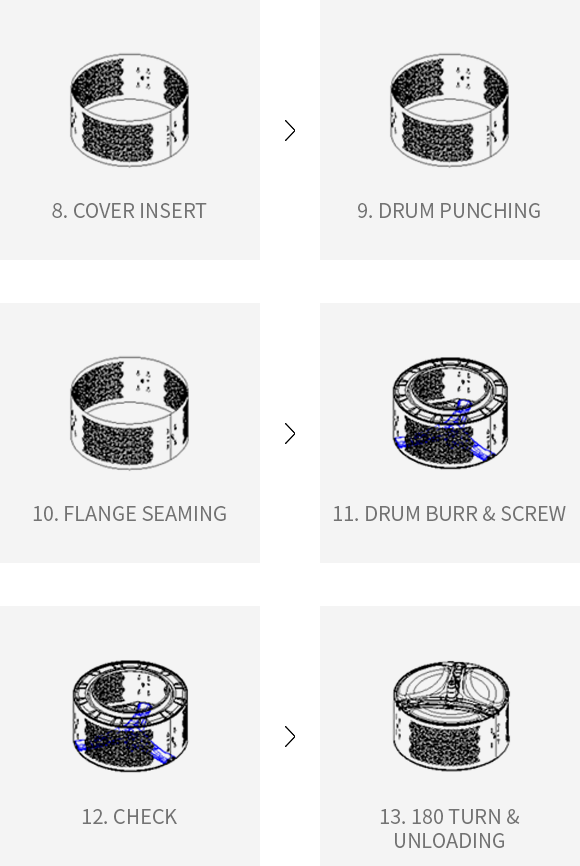

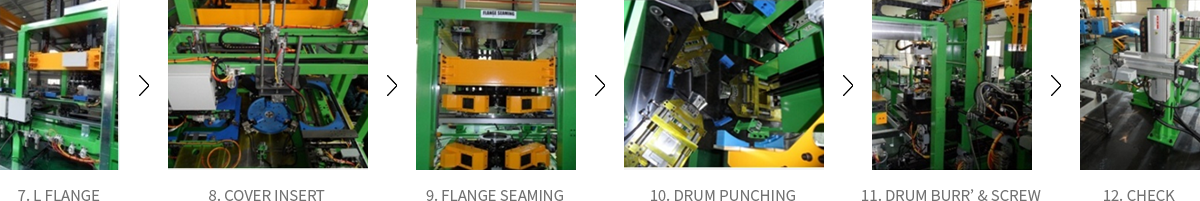

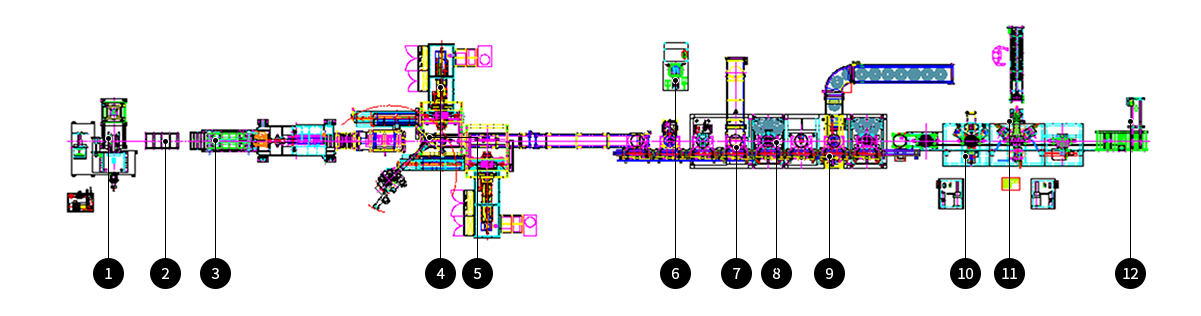

세탁기 - Spine Drum (Basket)

엔진 서브라인 제작설치

엔진 서브라인 제작설치 자동차 공장 의장 Line 제작설치

자동차 공장 의장 Line 제작설치 자동차 공장 의장 LineOLT 제작설치

자동차 공장 의장 LineOLT 제작설치 자동차 의장라인 머플러 장착공정

자동차 의장라인 머플러 장착공정

동기대차 제작 및 설치 자동차 의장라인 화이널 3라인

자동차 의장라인 화이널 3라인

EMS개조 제작설치 자동차 의장라인 서스펜션

자동차 의장라인 서스펜션

컨베어 제작 설치 자동차 의장라인 CPAD투입라인

자동차 의장라인 CPAD투입라인

제작설치 자동차 차체라인 BC EMS개조

자동차 차체라인 BC EMS개조

제작설치 자동차 차체라인 EMS 로딩

자동차 차체라인 EMS 로딩

DROP LIFTER 제작설치 자동차 차체라인 SIDE EMS 개조

자동차 차체라인 SIDE EMS 개조

제작설치 엔진조립라인

엔진조립라인 엔진조립라인_2

엔진조립라인_2 도어모듈 구리스 도포장치

도어모듈 구리스 도포장치 글로브 박스 완제품 비전 검사

글로브 박스 완제품 비전 검사 도어모듈 조립라인

도어모듈 조립라인 레귤레이터 자동 체결 및 검사라인

레귤레이터 자동 체결 및 검사라인 스커트 열융착기

스커트 열융착기 암레스트 조립라인

암레스트 조립라인

CLEAVING AUTOMATION

CLEAVING AUTOMATION CLEAVING AUTOMATION

CLEAVING AUTOMATION

TOP